You Make the Medicine,

We Preserve Efficacy.

Active Packaging Ensures Drug Products are Safe and

Effective When They Get to People who Depend on Them

Lowest Total Cost of Ownership

We help you consider your Total Cost of Ownership (TCO). The least expensive solution can cost more in the long-run. We help you make sense (and cents) of your expenses, so you can make an informed decision.

For the past 50 years, Multisorb has partnered with the top pharmaceutical manufacturers to preserve the efficacy of products so they get to the end-user safely, ready to perform and treat medical conditions to improve lives.

Backed By Science

For the past 50 years, Multisorb has partnered with the top pharmaceutical manufacturers to preserve the efficacy of products so they get to the end-user safely, ready to perform and treat medical conditions to improve lives. We have continuously advanced our sorbent technology to stabilize the most advanced drug chemistries.

3K+

Simulations Run

1k+

Products Stabilized

20B+

Units Manufactured

We work with companies in the healthcare industry to:

Reduce chemical and physical degradation of drug products

Get products to market faster by quickly diagnosing sorbent needs

Extend product shelf life and reduce loss from waste

Increase productivity with industry-leading dispensers

“

We had a technical challenge and Multisorb was the only company that coud provide a solution. We looked at other suppliers and they came back and told us they couldn’t do what we needed.

…

As shared by a leading pharmaceutical brand

…

Identifying the Correct Sorbent

Holistic Package Expertise

Our scientists develop an isotherm that shows the absorption capacity for a drug substance within it’s specific package.

Using the isotherm our team determines the optimum equilibrium relative humidity (ERH) and calculates the anticipated affects of moisture and/or oxygen over time. This data gives a clear indication of the amount of sorbent required for a specific application.

Ingress through flaws on induction seals or the primary package

Transmission through bottles or other barrier materials

Initial container headspace from exposure while being packaged

The drug product itself or other internal packaging components

Held to a Higher Standard

Multisorb’s quality is second-to-none. Our customers know that our packaging solutions protect their products and meet all regulatory requirements. Our Regulatory Affairs staff are experts who make sure our solutions conform to all regulatory guidelines.

Industry Certifications

- ISO 9001:2015 Registered

- GFSI FCCS 22000 Certified

- 21 CFR Parts 210-211 (cGMP) compliant

- Certified for EU 10/2011 on food contact

Delivering A Premium Product

Multisorb’s quality is second-to-none. Our customers count on our packaging solutions to protect their products and meet all regulatory requirements. Quality is built into our DNA, and we regularly conduct internal audits and host audits from our customers. Our scientists develop an isotherm that shows the absorption capacity for a drug substance within it’s specific package. Using the isotherm our team determines the optimum equilibrium relative humidity (ERH) and calculates the anticipated affects of moisture and/or oxygen over time. This data gives a clear indication of the amount of sorbent required for a specific application.

Product Spotlight | Multiform CSF Canister

Over 65% reduction in plastic material when compared with traditional canisters

- Higher absorption capacity per unit volume means one canister can be used instead of two

- One-piece design eliminates the possibility of loose desiccant spilling on manufacturing line or contaminating the product

- Universal dispensing eliminates excessive dispenser tooling changes and increases productivity

- Better performance at a comparable cost

CASE STUDY | Meeting Technical Challenges

The Challenge – A highly moisture-sensitive drug needed 2 grams of desiccant inserted into a small 45-cm3 sample bottle with a 20mm opening on a high-speed bottling line.

The Benefit – Today this brand has extended their distribution timeline, increased consumer appeal and accelerated sales.

Lowest Total Cost of Ownership

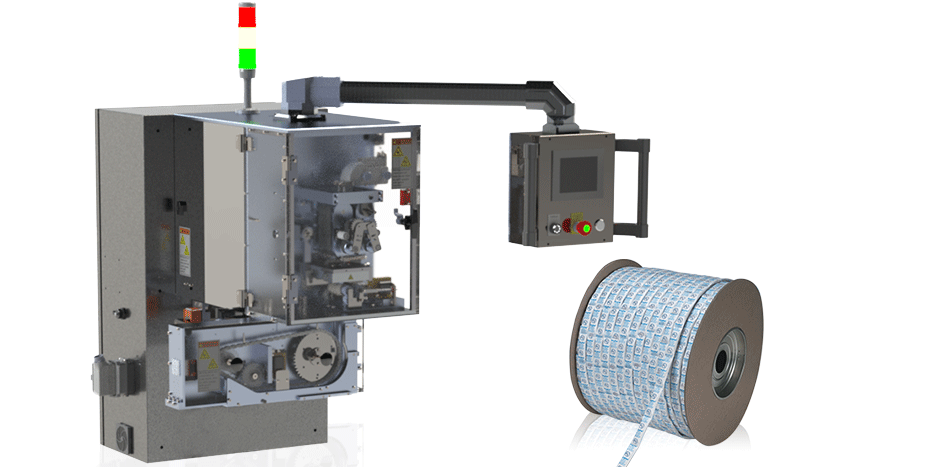

Look beyond the short term investment and buy the right equipment the first time. Multisorb dispensers operate at speeds up to 300 packets per minute and are remarkably reliable. Multisorb dispensers allow our customers to maximize their productivity and scale over time. We offer a one-stop solution for both the sorbent and the dispenser. Our speed and efficiency is backed by our service and support.

Seamless integration into any packaging line

Our dispensers integrate into existing packaging lines such as bottling, flow-wrapping, vertical (VFFS) or horizontal (HFFS) form fill seal, direct drop, custom gated drop chute, and multi-lane race track shuttle.

Buy what you need, protect what you have

Sorbents lose performance quickly when they are exposed in an open atmosphere. Our optional dry air or inert gas purge protects sorbent capacity during packaging operations.

Maximize output efficiency

Optional packet splicing station cabinet allows for continuous dispensing and enables operators to replace empty spools with a full one without stopping the dispenser.

Automation at work

The optional bottle reject system allows for continuous dispensing verifying that the sorbent has been inserted and removing problematic bottles from the line without stopping production.

Our Products

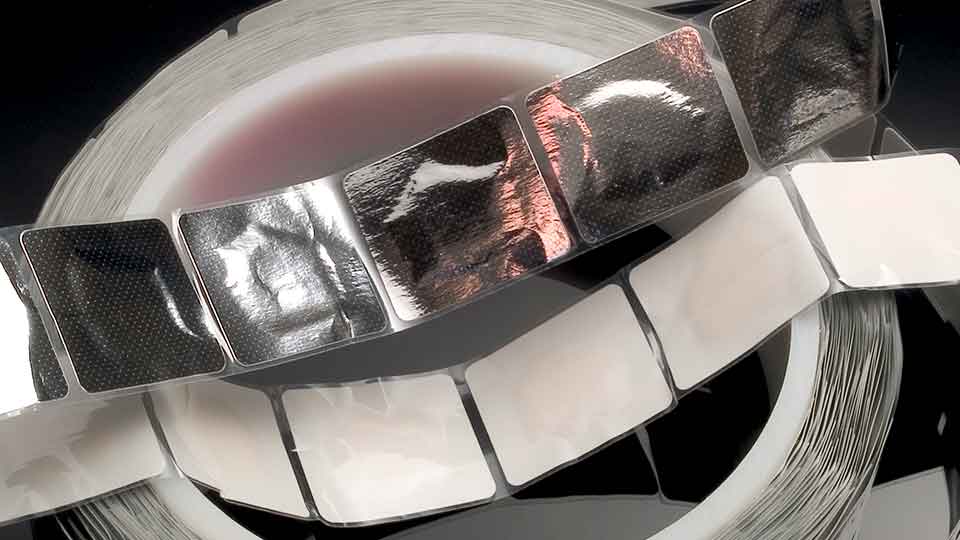

StripPax®

These extremely durable, moisture and/or volatile absorbing packets are available in a wide variety of sizes and fill types.

MiniPax®

Ideal for hand packaging operations, MiniPax Sorbent Packets are compact, extremely durable, non-dusting sorbent packets.

IntelliSorb®

Advanced Solutions for Moisture Regulation. Balance stability of products with intelligent moisture absorbing packets.

StabilOx® Packet

StabilOx oxygen absorbing packets eliminate oxygen to achieve better product stability. Up to 5x better performance.

Multiform CSF® Canister

With equivalent adsorption rate and capacity as loose-fill canisters, Multiform CSF canisters smaller and more effective.

SorbiCap®

Designed to give you a superior, non-dusting, inseparable, cost effective product that delivers effective adsorption rates.

StabilOx® Canister

StabilOx oxygen absorbing canisters eliminate oxygen to help you achieve better product stability. Up to 5x better performance.

Multiform CSF®

This compact sorbent solution provides twice the absorption capacity of a loose fill format, reducing sorbent size.

Multiforms®

Ideal for applications where space is limited, this ultra-strong, durable moisture absorber provides protection from moisture.

DesiMax®

Desiccant Adhesive patch that comes spooled on a release liner. Can be automated or applied manually.

PolySorb®

Space-saving desiccant that protects your product. Built-in sorbent protection that is invisible to your consumer.

Our Dispensers