Oxygen Absorbing Film: The Package Itself Absorbs Oxygen

There’s a lot of science behind food packaging. Manufacturers have to control the environment inside the package in order to preserve a food’s color, texture, taste, and smell.

To do so, an oxygen scavenger is typically added to the package. These scavengers are usually free-floating components, but a new kind of oxygen absorber is generating a lot of buzz for food manufacturers.

Before we talk about this innovative new oxygen absorber, let’s examine how problematic oxygen can be inside food packaging.

Oxygen can drastically alter food products

The level of oxygen inside a package can seriously affect food. Oxygen that’s trapped inside a food container can cause a variety of problems, including:

- Spoilage

- Mold growth

- Altered color

- Odd texture

- Foul odor

Oxygen scavengers keep food fresh on the shelf and sellable longer. This helps food manufacturers and retailers maximize their profits by increasing sales and reducing what’s referred to as “shrink”; which really just means throwing the food away.

When food spoils, manufacturers and retailers throw profits away. “Shrink” is an industry term used when food is thrown away because it has passed its expiration date. Shrink accounts for an estimated $165 billion in annual waste.

The usual solution

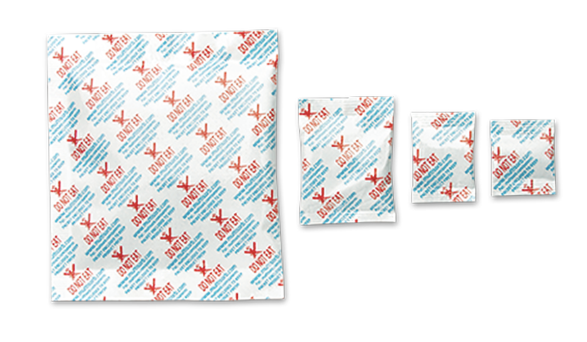

To combat these problems, some food brands maximize their sales and reduce waste with oxygen scavengers which absorb oxygen inside of a sealed package. They come in many different forms, including support cards, adhesive labels, or a packet, like this FreshPax below:

These solutions can be built-in or free-floating, in either case, they are sharing space inside the primary package with the food product. These types of solutions are commonly found in products like beef jerky, pepperoni, dried nuts, and vitamins, for example.

While an oxygen-absorbing packet is a simple and effective way to preserve the quality of food, manufacturers have a NEW option to consider.

The new solution

Rather than add a free-floating packet in with the food, manufacturers can now add a layer of oxygen-absorbing film to the package itself. The film is built into the package, so customers don’t even know it’s there – yet it keeps their food safe.

The film is impregnated with FreshPlus oxygen-absorbing resin and is fully integrated into the package containing beef jerky, for example. It can be used in pouches, bags, lidding film, and flow wrap.

The film offers the same effective oxygen-trapping benefits as the canisters or packets, but it’s unseen.

Interested in oxygen-absorbing film for your product? Let Multisorb custom design the right oxygen absorber for your product. Reach out to a design expert today.