APA 4000 Packet/Pouch Dispenser

High-Speed Sorbent Delivery for Relentless Production Lines

Engineered to Keep Your Line Moving

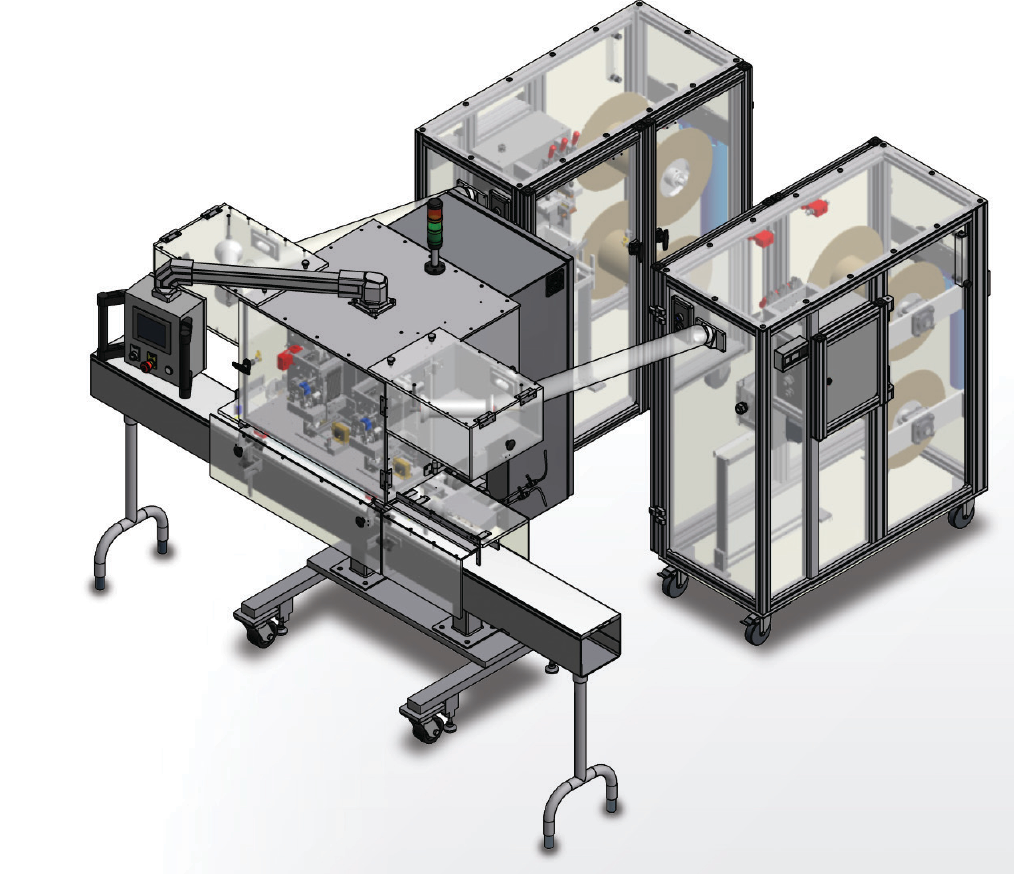

The APA 4000 serves as the engine of our StripPax® and StabilOx® Systems, matching Multisorb’s spooled sorbent packets with a dispenser built for nonstop production.

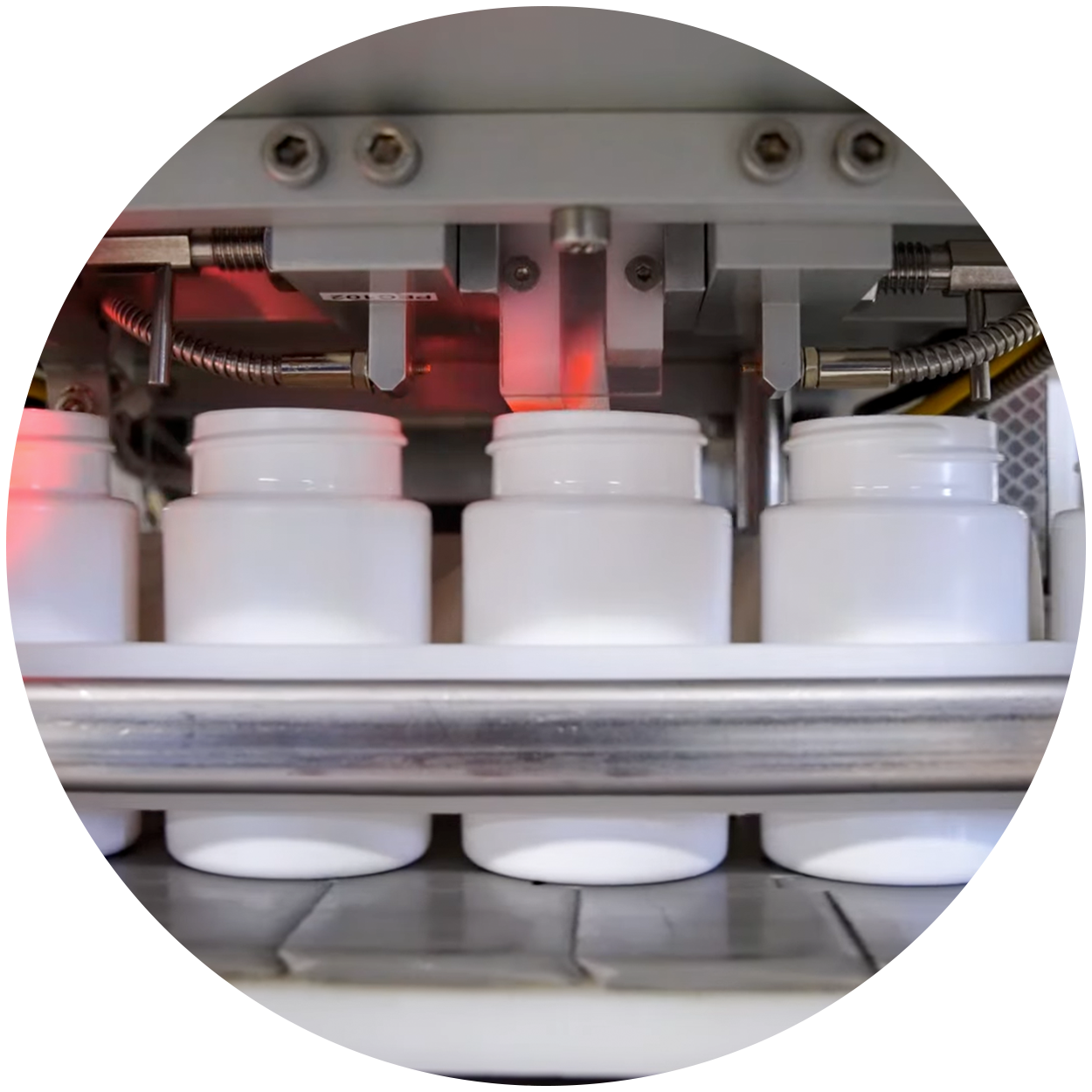

Two independent, servo-driven heads alternate automatically, so packet delivery continues while an operator splices a fresh roll or performs a quick wipe-down. Optical sensors confirm each packet is on target and feed data to the PLC, which adjusts speed on the fly to stay in sync with fillers running up to 300 containers per minute. The result is a compact unit that safeguards product integrity and keeps throughput high—shift after shift.

Key Performance Highlights

- Twin-Head Design: Two independent dispensing heads alternate automatically, sustaining output even during roll changes or maintenance.

- Uninterrupted Splicing Stations: Dual cabinets feed pre-spliced rolls, so packet supply keeps pace with your fastest fillers.

- Up to 300 Packets per Minute: Whether you need one or two packets per container, the servo-driven system maintains consistent placement accuracy.

- Smart Control Interface: An intuitive color touchscreen with PLC integration lets operators select packet count, monitor status, and trigger rejects in seconds.

- Optional Bottle-Reject Module: Faulty inserts never advance to capping, eliminating downstream rework.

APA 4000 Specifications

- Maximum Throughput: 300 packets/min (single or dual drop)

- Compatible Packet Formats: StripPax® and StabilOx® spooled packets

- Dispensing Heads: Twin, alternating or simultaneous

- Packet Feed: Dual in-feed from separate splicing cabinets

- Interface: 7-in. color HMI touchscreen + PLC

- Footprint: 1,016 mm (L) × 813 mm (W) × 1,727 mm (H) (approx.)

- Utilities: 110/220 VAC, 50/60 Hz; 80 psi compressed air

- Options: Bottle-reject station, remote diagnostics, CRP preventive-maintenance program

Ready to Accelerate Your Moisture-Control Workflow?

Talk with a Multisorb packaging specialist today and schedule a live APA 4000 demo.

Seamless Integration, Minimal Downtime

Installation is straightforward: the APA 4000 bolts onto most continuous or intermittent bottling and pouching lines with only a mounting bracket and a simple handshake signal to your existing PLC.

Long packet rolls reduce the number of changeovers, while dual splicing cabinets let operators prep the next roll without stopping the line, virtually eliminating unplanned pauses. Closed-loop servo control places every packet flat and centered to maintain cGMP compliance, and our continuous reliability program supplies scheduled inspections, wear-part kits, and performance reports—helping maintenance teams keep overall equipment effectiveness at its peak.

APA 4000 FAQs