Multisorb APA Dispensing Equipment

Accelerate Your Productivity

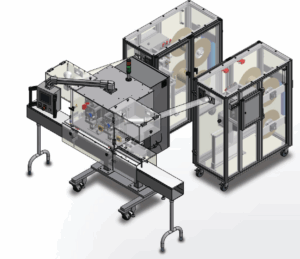

Ensure Seamless Product Line Operations With Custom Packet Dispensers

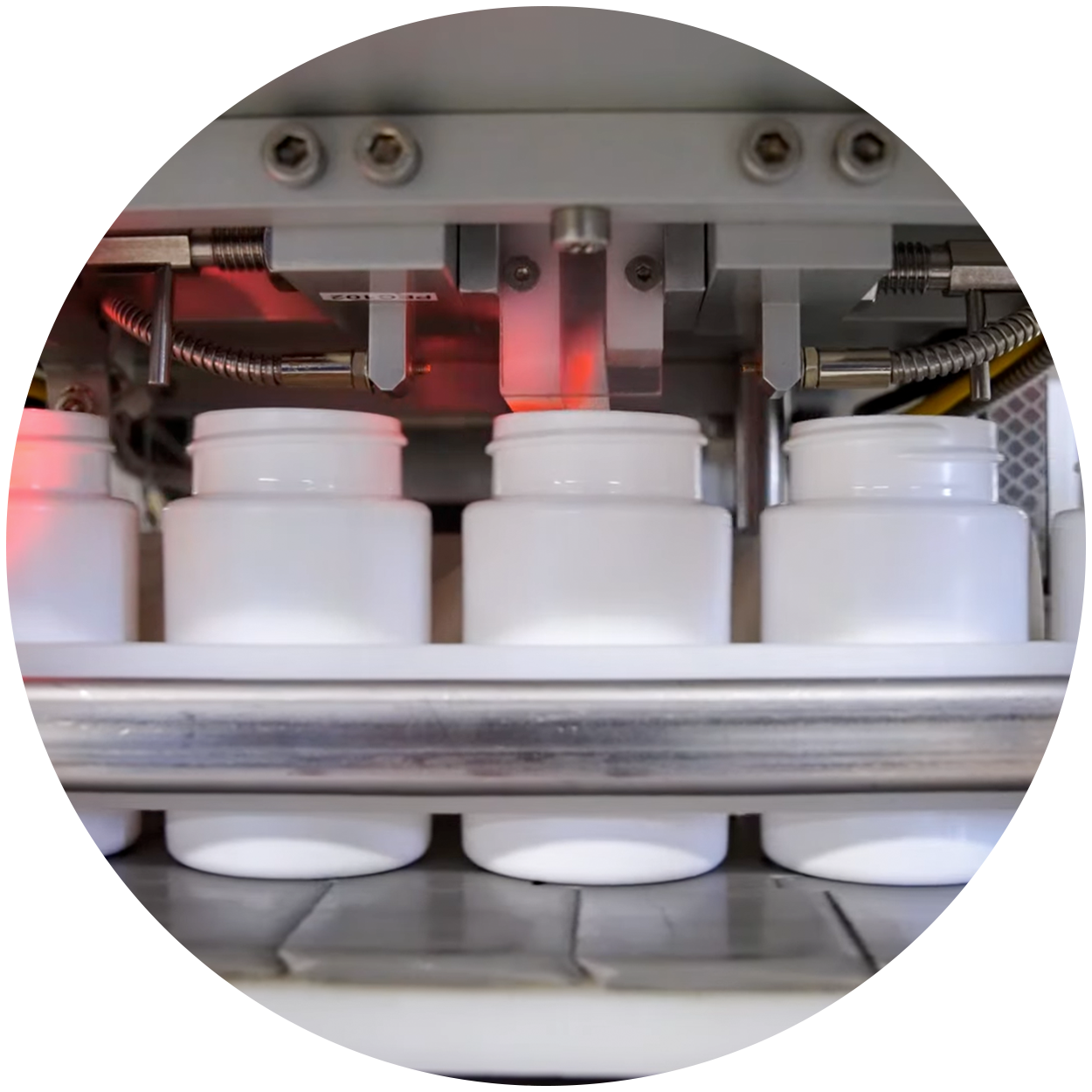

With over twenty-five years in dispensing solutions and over sixty years of expertise in active packaging, Multisorb delivers advanced dispensing equipment for oxygen absorbers and desiccants. These innovative machines are designed to optimize product line operations, providing precise and reliable dispensing solutions that enhance productivity and reduce waste. Along with our full-service installation and preventative maintenance program, we perform routine operational care to keep dispensing equipment efficient.

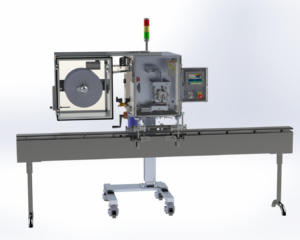

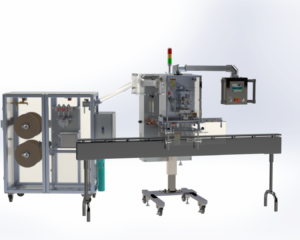

Multisorb’s industry-leading technology ensures seamless integration into existing processes, helping businesses maintain constant uptime while meeting demanding production schedules. By choosing Multisorb’s packet dispensers, you’re investing in equipment that streamlines processes and upholds the integrity of your packaged products.

Browse Our Assortment of Sorbent Dispensers

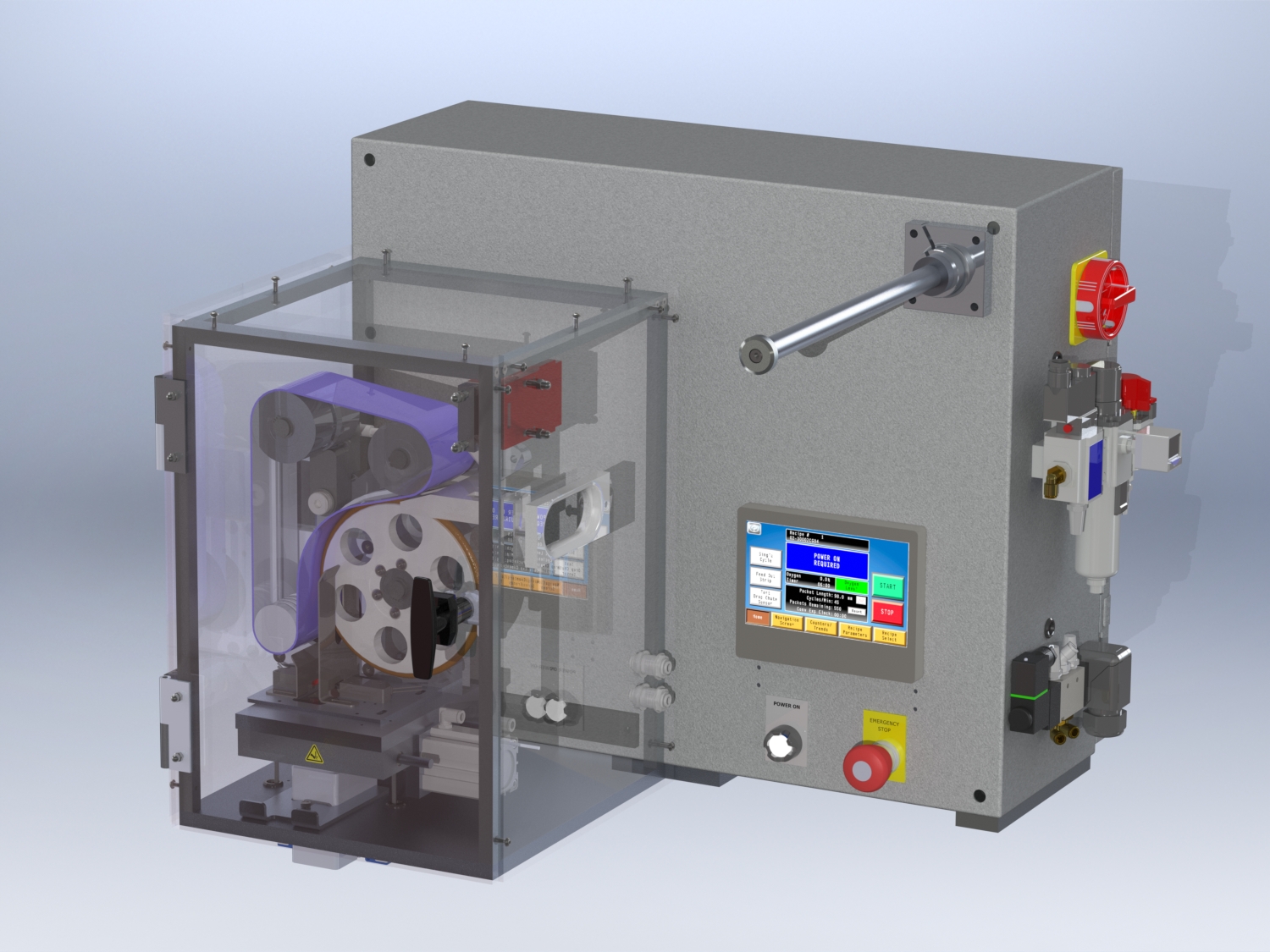

Multisorb offers full-service installation for a multitude of oxygen absorber and desiccant inserter machines, each designed to suit your product’s needs and enhance the efficiency of your product line. All of our APA® Series dispensers are built in the U.S. and designed to meet CE standards for constant uptime and reliable performance.

Optimize Your Packaging Operations

Maintain constant uptime on your product line with Multisorb’s advanced sorbent dispenser equipment. Contact us today for professional guidance and full-service installation tailored to your needs.

Ensure Optimal Performance Through Rigorous Testing

Multisorb’s simulation solutions precisely determine the ideal sorbent type and dispenser equipment, optimizing stability, packaging efficiency, and product performance for your needs. These evaluations include environmental testing, compatibility assessments, and production simulations to ensure reliable sorbent application and dispenser efficiency. Multisorb’s advanced testing methods guarantee that their equipment seamlessly integrates with packaging lines while delivering precise and consistent sorbent placement. By rigorously analyzing product behavior under real-world conditions, we ensure solutions provide maximum protection for customers’ products, maintaining constant uptime and reliable quality across various industries.

Simulations Completed

Take Advantage of Our High-Quality Dispensing Equipment

Multisorb’s full-service sorbent packet dispenser solutions offer unparalleled efficiency and precision in active packaging applications. Designed for oxygen absorbers and desiccants, these systems ensure accurate dispensing, minimizing waste and maximizing reliability in your production process. Integrating reliable dispensing equipment into your operations allows you to maintain constant uptime, enhance packaging consistency, and ensure optimal product integrity.

Multisorb’s oxygen absorber and desiccant machines stand out from the competition, helping your business meet rigorous demands while supporting faster production cycles and ensuring long-term product stability.

Frequently Asked Questions About Packet Dispensers